Understanding Road Traffic Markings and Their Applications

What Are Road Traffic Markings?

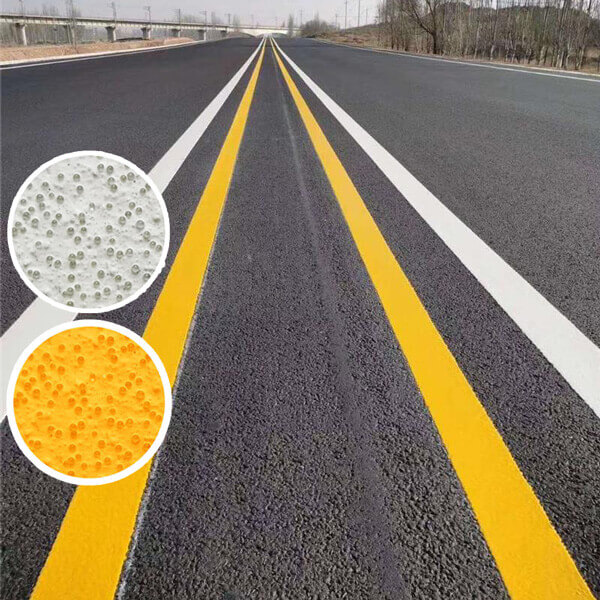

Road traffic markings are essential components of roadway infrastructure, guiding vehicles and ensuring traffic safety. These markings come in various types, including:

- Thermoplastic Road Markings: One of the most commonly used markings due to its durability, cost-effectiveness, and quick application.

- Cold Paint Road Markings: Applied at ambient temperatures, typically used for temporary or low-traffic areas.

- Colored Anti-Skid Markings: Designed to enhance road grip and visibility, often found in high-risk areas.

- Vibratory Reflective Markings: These markings improve visibility at night and during adverse weather conditions.

- Preformed Road Markings: Manufactured in a controlled environment and applied directly onto the road surface.

Key Characteristics of Road Markings

Road markings are exposed to various environmental conditions such as sunlight, rain, snow, and vehicle wear. As a result, they must meet strict performance requirements:

- Fast drying time to minimize traffic disruption.

- High reflectivity and vivid color for improved visibility during both day and night.

- Skid resistance and durability to ensure safety and longevity.

Applications of Road Markings

Road markings are widely used in various locations, including highways, industrial zones, factory parking lots, underground garages, school campuses, and residential areas. Depending on the application, road markings can be divided into two categories:

- Cold Paint Markings: Applied using specialized road paint, manually sprayed for uniform thickness and clarity. Common applications include parking lines, no-parking zones, directional arrows, and speed bumps.

- Thermoplastic Markings: These consist of a blend of resin-based materials, glass beads, pigments, and fillers. The formulation enhances adhesion, prevents discoloration, and improves resistance to wear.

Thermoplastic Reflective Markings

To enhance nighttime visibility, thermoplastic markings often incorporate reflective glass beads. These beads, being colorless and transparent, reflect light from vehicle headlights back toward the driver, improving visibility and road safety.

Thermoplastic Road Marking Application Process

- Surface Preparation: The road surface is cleaned and primed with a reflective glass bead-based primer.

- Material Heating: Thermoplastic paint is heated in a specialized melting machine to a temperature of 180°C to 220°C and stirred for approximately ten minutes before application.

- Marking Layout: The designated areas are measured and marked according to the planned design.

- Application: The thermoplastic material is applied, and reflective glass beads are spread over the markings to enhance visibility. The final marking thickness ranges from 1.5 to 1.8 mm.

Conclusion

Road traffic markings play a crucial role in guiding vehicles and ensuring road safety. Choosing the right type of marking depends on durability, reflectivity, and specific traffic requirements. Proper application and maintenance ensure that markings remain effective in all conditions.