Choice of Parking Lot Paint: Types, Benefits, and Applications

Parking lot paint is essential for maintaining clear markings, improving safety, and enhancing the aesthetics of commercial and residential properties. The three most common types are Thermoplastic Road Marking Paint, Cold Solvent Road Marking Paint, and Two-component Road Marking Paint. Each has unique properties, making them suitable for different environments and budgets.

1. Thermoplastic Road Marking Paint

What Is It?

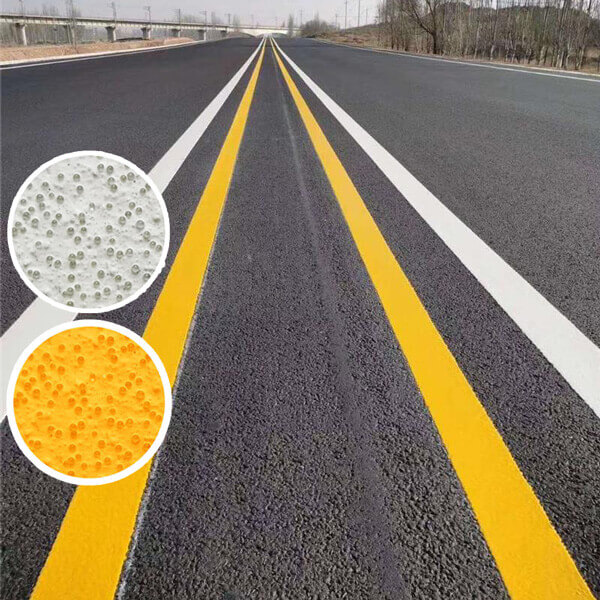

Thermoplastic paint is a durable, heat-applied marking material made from synthetic resins, glass beads (for reflectivity), pigments, and fillers. It is melted at 180–220°C (356–428°F) and applied to asphalt or concrete surfaces.

Key Features:

- ✔ Extreme Durability – Lasts 3–5 years under heavy traffic (vs. 1–2 years for standard paints).

- ✔ High Visibility – Contains 30–50% glass beads for superior nighttime reflectivity (≥ 400 mcd/m²/lx).

- ✔ Fast Application – Sets in 1–3 minutes, allowing quick reopening of parking lots.

- ✔ Weather Resistance – Performs well in extreme heat, cold, and UV exposure.

Best For:

- ✅ High-traffic areas (shopping malls, airports, highways).

- ✅ Long-term projects where frequent repainting is impractical.

- ✅ Regions with harsh weather conditions.

Industry Standards:

- EN 1436 (EU) – Reflectivity & skid resistance.

- ASTM D713 (USA) – Performance specifications.

2. Cold Solvent Road Marking Paint

What Is It?

Cold solvent paint is a traditional, oil-based marking solution that dries through solvent evaporation. It is applied at ambient temperature and does not require heating.

Key Features:

- ✔ Easy Application – No special equipment needed (unlike thermoplastic).

- ✔ Lower Initial Cost – More affordable than thermoplastic or two-component options.

- ✔ Decent Durability – Lasts 1–2 years with moderate traffic.

Limitations:

- ❌ Slower Drying Time – Takes 10–30 minutes to dry.

- ❌ Lower Reflectivity – Typically contains 15–25% glass beads.

- ❌ Shorter Lifespan – Requires more frequent repainting.

Best For:

- ✅ Low-to-medium traffic parking lots (apartment complexes, office parks).

- ✅ Temporary or budget-conscious projects.

- ✅ Areas with mild weather conditions.

Industry Standards:

- AASHTO M 249 (USA) – Standard for solvent-based traffic paint.

3. Two-Component Road Marking Paint

What Is It?

Two-component (2K) paint consists of a resin and a hardener that chemically react to form an ultra-durable coating. It is applied via spray or extrusion and cures within 5–20 minutes.

Key Features:

- ✔ Superior Longevity – Lasts 5–8 years, outperforming thermoplastic in abrasion resistance.

- ✔ Chemical & Fuel Resistance – Ideal for gas stations and industrial sites.

- ✔ High Reflectivity – Can achieve ≥ 500 mcd/m²/lx with premium glass beads.

Limitations:

- ❌ Higher Cost – More expensive than thermoplastic or cold solvent paint.

- ❌ Complex Application – Requires precise mixing of components.

Best For:

- ✅ High-end commercial properties (hospitals, universities, logistics hubs).

- ✅ Areas exposed to chemicals, oils, or heavy machinery.

- ✅ Long-term investments where minimal maintenance is desired.

Industry Standards:

- ISO 12944 (Global) – Corrosion protection standards.

- DIN 67530 (Germany) – Reflectivity requirements.

Which Parking Lot Paint Should You Choose?

| Factor | Thermoplastic | Cold Solvent | Two-Component |

| Durability | 3–5 years | 1–2 years | 5–8 years |

| Cost | Medium | Low | High |

| Drying Time | 1–3 min | 10–30 min | 5–20 min |

| Best Use Case | High traffic | Budget projects | Extreme durability |

Final Recommendation:

- For long-term durability → Two-component paint (best ROI).

- For quick, cost-effective marking → Cold solvent paint.

- For heavy traffic & fast application → Thermoplastic paint.