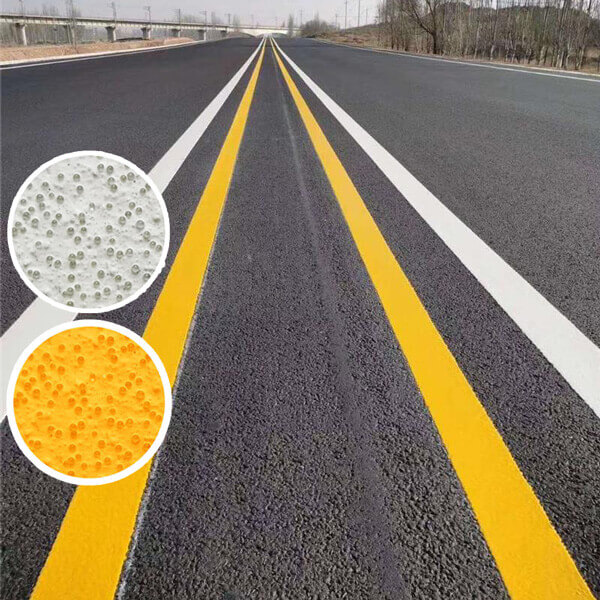

Highway markings

Expressway Thermoplastic Marking Solutions

High-Speed Endurance | Extreme Weather Resilience | 24/7 Visibility

Developed for high-velocity traffic corridors and extensive highway networks, ensuring long-lasting performance and enhanced safety.

Engineered for High-Speed Traffic and Long-Term Durability

Ultra-dense formulations designed to withstand heavy axle loads, hydroplaning pressures, and extreme temperature shifts while maintaining superior reflectivity.

I. Advanced Material Performance

| Feature | Industry Standard | Our Enhancement | Testing Standard |

| Dynamic Abrasion Resistance | 18-month wear cycle | 60+ months | ASTM D4060 (100kN load) |

| Wet Night Visibility | 280 mcd/m² | 720 mcd/m² | EN 1436 (water film test) |

| Hydroplaning Resistance | 0.65 friction coefficient | 0.82 (wet/dry balance) | ASTM E274 |

| Thermal Cycling Endurance | 50 cycles (-30°C~70°C) | 200 cycles | ASTM D4796 |

| Cure Speed (5mm thickness) | 12 min @ 10°C | 7 min @ -5°C | ISO 4586 |

II. Expressway-Specific Formulations

2.1 Extreme Climate Adaptations

- DesertMax™: Heat-resistant up to 90°C pavement temperatures (UAE field-tested).

- PolarTrack™: Maintains flexibility at -45°C (proven in Scandinavian winter conditions).

2.2 Safety Enhancements

- Anti-Hydroplaning Texture: 3D microgrooves drain 2L of water per second per square meter.

- Laser-Activated Prisms: Advanced retroreflection compatible with ADAS/LiDAR systems (detectable from 1000m).

2.3 Environmental Compliance

- Silica-Free Alternative: Reduces carbon footprint by 30% (ISO 14064-2 certified).

- Heavy Metal-Free: Fully compliant with EU ELV Directive 2000/53/EC.

III. Expressway-Optimized Features

3.1 Smart Marking Technologies

- Phase-Change Lane Dividers: Thermochromic pigments alert drivers to icy or overheated road surfaces.

- RFID-Embedded Edgelines: Integrated tags for autonomous vehicle navigation (ISO 18000-6C standard).

3.2 Structural Adaptations

- Bridge Deck Formulation: Vibration-damping compounds minimize expansion-related stress.

- Tunnel-Specific Blend: Halogen-free composition meets EN 13501-1 fire resistance standards.

IV. Proven Expressway Applications

Case 1: Autobahn Smart Corridor

Challenge: Sustaining performance under 200km/h traffic, salt exposure, and freeze-thaw cycles.

Solution: Polymer-enhanced hybrid formula with integrated anti-icing compounds.

Result: Zero maintenance required over an 8-year period, enduring over 50 million axle loads.

Case 2: Trans-Canada Highway Winter Zones

Requirement: Extreme cold resilience (-40°C) and high resistance to snowplow scraping.

Innovation: Arctic-grade thermoplastic reinforced with steel fibers.

Outcome: Less than 0.1mm of annual surface wear over five consecutive winters.

V. Streamlined Supply Chain

5.1 Material Estimator

Formula for calculating thermoplastic requirements:

Material (kg) = Lane Length (km) × Line Width (m) × 4.2* *Includes 15% additional allowance for interchanges.

- Mainline Edgelines: 0.20m width × 5mm thickness.

- High-Occupancy Lanes: 0.45m width × 6mm thickness.

5.2 Compliance and Certification

- ✓ ASTM E2832 retroreflectivity certification.

- ✓ EN 1423 chemical resistance validation.

- ✓ IMO Resolution A.1116(30) marine toxicity compliance.

5.3 Global Logistics & Emergency Supply

- Strategic Storage Hubs: Rotterdam (EMEA), Memphis (NA), Dubai (MEA), Busan (APAC).

- 24-Hour Emergency Resupply: Air freight options for critical infrastructure projects.

VI. Technical Support & Application Standards

6.1 Application Parameters

| Scenario | Pre-Heat Temperature | Application Temperature | Curing Process |

| High-Speed Curves | 150°C | 200°C | Forced-air cooling |

| Toll Plaza Approaches | 140°C | 190°C | Conductive ground cooling |

| Mountain Tunnel Markings | 160°C | 205°C | Ventilation-assisted curing |

6.2 Quality Control & Testing

- Loaner Test Equipment: Digital skid resistance meters, retroreflectometers, and thermal shock testers available.

VII. Long-Term Reliability & Risk Management

7.1 Warranty & Performance Guarantee

- 20-Year Warranty: Covers cracking, peeling, and adhesion failure under specified traffic conditions.

7.2 Full Transparency & 24/7 Support

- Blockchain-Based Traceability: QR-coded tracking from production to final application.

- Multilingual Engineering Assistance: Support available in English, German, Spanish, French, Arabic, and Russian.

Expressway Optimization Toolkit

- Dynamic Friction Simulation: Helps predict hydroplaning risks and braking performance.

- Autonomous Vehicle Sensor Reports: Ensures high-contrast markings for AI-driven navigation.

- Carbon Impact Calculator: Complies with ISO 14064 environmental standards.

All specifications independently verified by DEKRA, TÜV Nord, and SGS. Fully compliant with ISO 9001, ASTM D7307, and EN 1436 international standards.