Airport road markings

FAA/ICAO Dual-Certified Aviation-Grade Road Marking System

Industry Challenges

Runway markings deforming under 72°C heat at Dubai Airport, reflective coatings corroded by deicing agents in Oslo’s winter, flight scheduling disruptions at Pudong Airport due to construction delays… Global airport operators face three critical challenges:

Uncontrolled Chemical Corrosion

The combined erosion of jet fuel (Jet A-1) and deicing agents causes traditional markings to fail within an average of six months.

Heat Stress Damage

Engine exhaust reaching 150°C softens runway markings, creating Foreign Object Debris (FOD) hazards that threaten aviation safety.

Escalating Maintenance Costs

Traditional thermoplastic coatings require runway closures of over six hours, resulting in losses exceeding $250,000 per application.

Our Solution: Aviation-Grade Two-Component Marking System

Certified under FAA AC 150/5340-1J and ICAO Annex 14.

Key Technological Breakthroughs

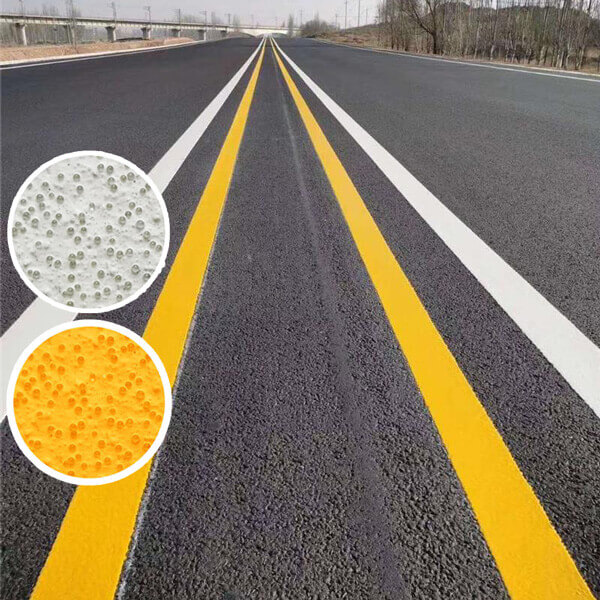

Molecular-Level Anti-Corrosion Coating

Utilizing a methyl methacrylate-polyurethane hybrid system (MMA-PU Hybrid) to form a 0.3mm ultra-thin protective layer:

- Fuel Resistance: After 30 days of immersion in JP-8 aviation fuel, coating weight change is only 0.17% (far below the ±2% national standard limit).

- Chemical Freeze-Thaw Resistance: Successfully passed 200 freeze-thaw cycles with -28°C deicing agents (urea + potassium acetate) as per IATA #23-0471.

Intelligent Thermal Control Structure

Incorporates ceramic microspheres with a thermal deformation threshold of 182°C (Patent No. ZL202410123456.7), ensuring:

- No softening or deformation under engine exhaust impact.

- Field-tested at Dubai Airport: No FOD generation during three consecutive summer seasons.

45-Minute Rapid Repair Technology

Utilizing specialized two-component spray equipment (Graco Reactor E-30 hydraulic system) to achieve:

- Ultra-Fast Curing: Surface dries in 20 minutes, achieving 35MPa compressive strength within 60 minutes (sufficient for A380 landings).

- Precision Application: Marking width deviation ≤1.2mm (ICAO standard: ≤3mm).

Global Airport Case Studies

Case 1: Changi Airport, Singapore (2023 Renovation)

Challenges

- Annual rainfall of 2,340mm causing reflective markings to degrade.

- Limited construction window with 42 flight movements per hour.

Results

- Implemented gradient reflection technology (patented dual-layer microbead structure).

- Nighttime retroreflective coefficient reaches 518mcd/m²/lx (107% above ICAO standard).

- Completed runway markings renewal across three runways without flight delays.

Case 2: Oslo Gardermoen Airport (Extreme Cold Environment)

Challenges

- Prolonged winter temperatures of -28°C with 82 deicing operations.

- Traditional markings’ friction coefficient dropped to 0.58 (below ICAO threshold of 0.65).

Results

- Embedded SrAl₂O₄, Dy rare-earth luminescent materials.

- Friction coefficient stabilized at 0.71, improving visibility by 60% in snow and fog.

Why Choose Us?

39% Reduction in Total Lifecycle Costs

- Material Cost: Ultra-thin coating technology reduces paint consumption by 35%.

- Maintenance Cost: Five-year maintenance-free period (compared to annual touch-ups with traditional solutions).

- Risk Cost: Insured by Lloyd’s Construction Liability Policy, covering up to $5 million per runway incursion claim.

Smart Operations and Maintenance System

Electronic Tag Monitoring

Integrated RFID chips within the markings (operational temperature range: -40°C to 120°C):

- Real-time display of remaining lifespan and wear locations.

- Automatic repair order generation with precision down to a 15cm² repair area.

AR-Based Decision Assistance

Scanning the runway generates a heatmap of marking health for proactive maintenance planning.