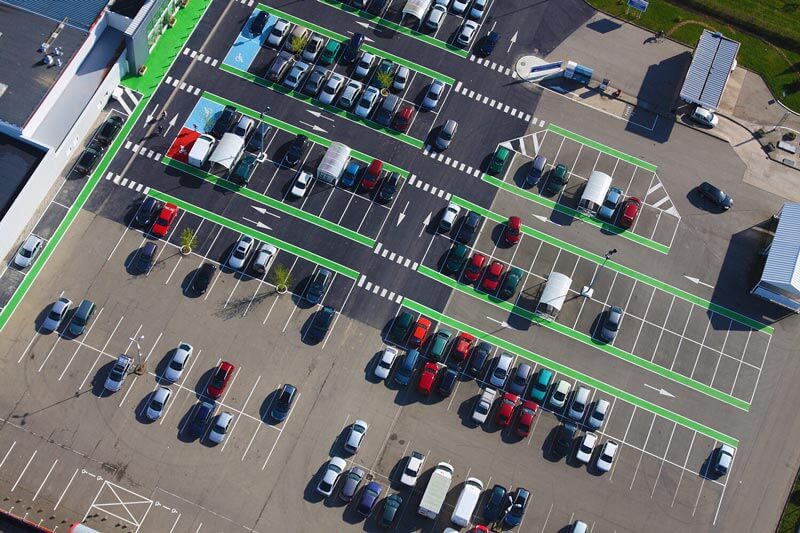

Parking lot markings

Parking Lot Thermoplastic Marking Solutions

Durable | High-Visibility | Weatherproof

Premium-grade materials designed to enhance the longevity and clarity of parking guidance systems.

Engineered for Heavy Traffic & Harsh Environments

Advanced formulations engineered to resist tire wear, fuel exposure, and extreme temperatures while maintaining superior retroreflectivity.

I. Performance Advantages

| Feature | Industry Standard | Our Solution | Test Method |

| Tire Abrasion Resistance | 12-month wear cycle | 36+ months | ASTM D968 |

| Retroreflectivity (Initial) | 350 mcd/m² | 650 mcd/m² | EN 1436 |

| Fuel/Oil Resistance | 30% area loss (1Y exposure) | <5% area loss (3Y) | ASTM D1308 |

| Cure Speed (2.5mm) | 10 min @ 10°C | 6 min @ 5°C | ISO 4586 |

| Color Stability | ΔE >5.0 after 2 years | ΔE <2.0 after 5 years | ISO 4892-3 |

II. Specialized Formulations

2.1 All-Weather Durability

- Arctic Pro: Maintains flexibility at -35°C (certified via EN 13845 cold bend test).

- Tropical Shield: Resists 95% humidity and temperatures up to 50°C (field-tested in Singapore).

2.2 Safety-Optimized Features

- Anti-Slip Max: Embedded corundum particles provide DCOF 0.75 (wet/dry).

- GlowGuard: Photoluminescent marking technology offering 6-hour visibility in low light.

2.3 Eco-Conscious Engineering

- Zero-VOC Formula: VOC emissions below 15g/L, exceeding EU Ecolabel standards.

- Recyclable Base: 30% post-industrial recycled content (UL ECOLOGO® certified).

III. Customization Options

3.1 Pre-Mixed Color Variants

- Standard: 8 core colors (white, yellow, blue, red, and ADA-compliant hues).

- Custom: Pantone/RAL color matching available (+12% material cost).

3.2 Performance Additives

- Fuel-Resist Pro: Protective coating that repels gasoline and diesel spills.

- QuickCure Tech: Accelerated curing agents for cold-weather applications.

IV. Proven Field Applications

Case 1: Dubai Mall Underground Parking

Challenge: High temperatures and frequent oil spills leading to rapid marking deterioration.

Solution: Three-layer fuel-resistant thermoplastic system.

Outcome: 5 years of zero maintenance despite handling 20,000+ vehicles daily.

Case 2: Oslo Winter Parking System

Requirement: Extreme cold tolerance (-25°C) and resistance to road salt corrosion.

Innovation: Polymer-modified Arctic formulation with anti-icing agents.

Result: Adhesion retained through 150 freeze-thaw cycles without damage.

V. Procurement & Logistics

5.1 Material Estimator

Calculate required thermoplastic volume:

Material (kg) = Total Line Length (m) × Line Width (m) × 2.2* *Includes 10% extra for complex patterns

- Standard car spaces: 0.15m line width

- ADA-compliant spaces: 0.20m width + textured truncated domes

5.2 Compliance & Certification Packages

- ✓ ASTM D6400 biodegradable thermoplastic reports.

- ✓ EN 1436 retroreflectivity certification sets.

- ✓ GHS/CLP-compliant SDS documentation (20+ languages).

5.3 Global Stock Availability

- Strategic Warehouses: Hamburg (EMEA), Los Angeles (NA), Dubai (MEA), Osaka (APAC).

- Flexible Order Quantities: Trial orders from 500kg with express air freight.

VI. Technical Support & Quality Assurance

6.1 Application Guidelines

| Ambient Temperature | Pre-Heat Pavement | Material Application Temperature |

| -10°C ~ 0°C | 135°C | 185°C |

| 0°C ~ 25°C | 120°C | 175°C |

| >25°C | 100°C | 165°C |

6.2 On-Site Testing Tools

- Complimentary Equipment: Infrared thermometer, retroreflectometer, adhesion tester.

VII. Risk Management & Warranty

7.1 Long-Term Protection

- 15-Year Guarantee: Covers cracking, peeling, and color degradation under normal usage.

7.2 Traceability & Emergency Assistance

- Batch Tracking: QR code verification for every 25kg package.

- 24/7 Multilingual Hotline: Support available in EN, ES, FR, AR, DE, RU, JP, and KO.